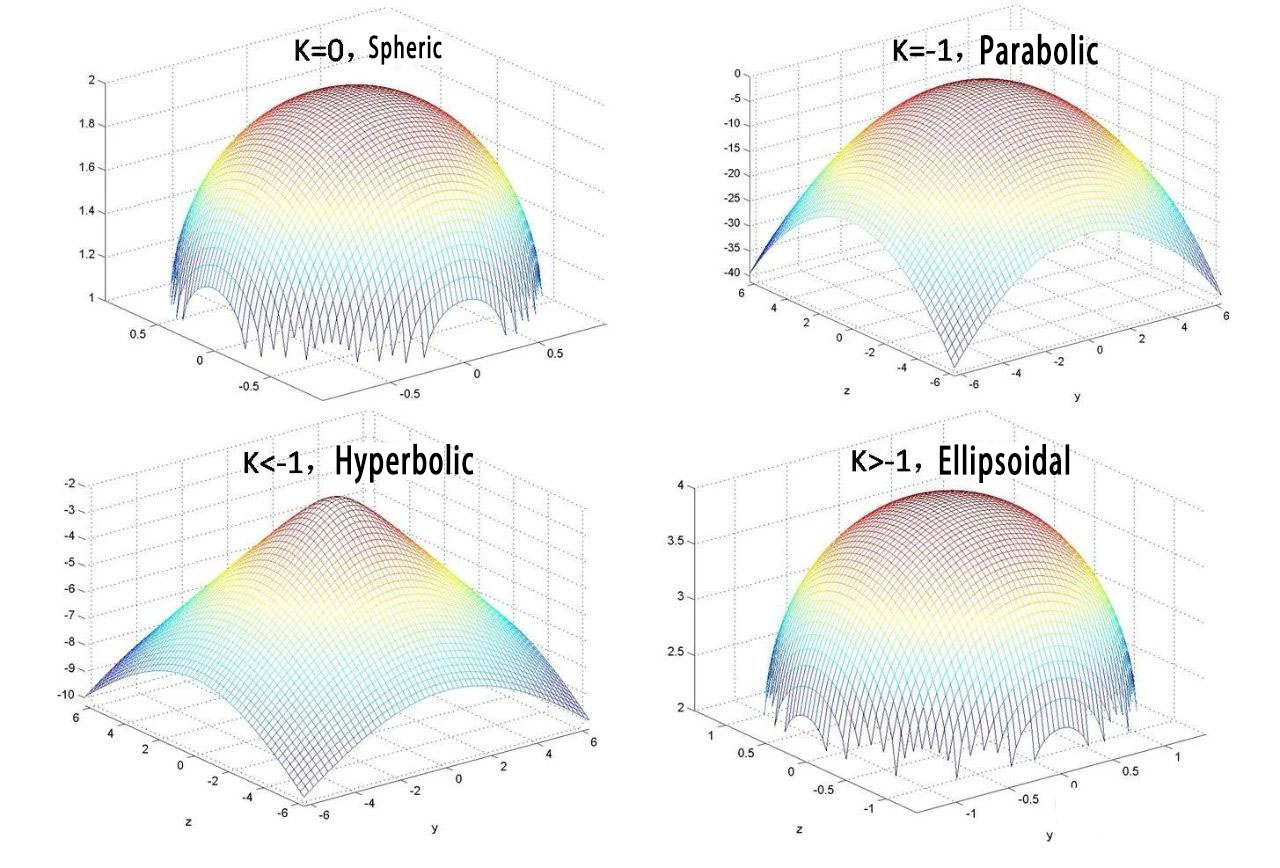

Aspherical optical elements (aspheres) are transformative components in modern optical systems, including motorized zoom lenses. Unlike traditional spherical lenses, which feature uniform curvature, aspheres have a continuously varying curvature from the center to the edge. This unique design enables superior aberration correction, system miniaturization, and enhanced optical performance.

1. Aberration Correction:

Spherical Aberration Elimination: Aspheres focus parallel light rays to a sharp point, whereas spherical lenses cause image blur due to spherical aberration. This ability allows aspheres to replace multiple spherical lenses, simplifying lens designs.

Example: A 10× zoom lens design for smartphones achieved a compact profile (thickness <6.5 mm) by incorporating aspheric elements instead of conventional spherical components.

2. System Miniaturization and Cost Efficiency:

Compact Designs: By replacing 5–6 spherical lenses with 1–2 aspheres, systems can be made lighter, smaller, and more cost-effective. This reduction in component count lowers material costs, mechanical tolerances, and calibration steps while maintaining high performance.

Example: Smartphone periscope zoom lenses leverage aspheres to deliver high-resolution imaging in constrained spaces.

3. Enhanced Optical Performance:

Tailored Curvature: Aspheres allow for precise adjustments in curvature, enabling superior performance in systems with large apertures, wide fields of view, or stringent size requirements.

The complex geometry of aspherical lenses requires advanced manufacturing techniques. Key methods include:

1. Material Removal Methods:

CNC Milling/Polishing: A standard method for prototyping and low-volume production. CNC machines offer high precision and automated adjustments for complex shapes.

Ion Beam/Magnetorheological Polishing: Used for ultra-smooth surface finishes.

2. Material Shaping Methods:

Injection Molding: A cost-effective approach for mass production, but it requires specialized molds and precise temperature control.

Glass Hot Pressing: Suitable for high-temperature-resistant lenses, often used in infrared applications.

3. Additive Methods:

Vacuum Coating Replication: Creates precise surface layers for replication, enabling high-quality aspheric lenses with minimal material waste.

Aspherical optical elements are revolutionizing motorized zoom lenses and other optical systems by enabling compact, high-performance designs. Their ability to correct aberrations, reduce component count, and adapt to advanced manufacturing techniques makes them indispensable in both specialized and consumer applications.

Bena Optics is a leading provider of high-performance aspherical optical elements, designed to meet the demands of modern optical systems. Our precision-engineered aspheres deliver superior aberration correction, miniaturization, and optical efficiency, making them ideal for applications in consumer electronics, and medical optics.

With a focus on innovation and quality, Bena Optics’ aspherical lens solutions are tailored to meet the specific needs of our customers. Explore our range of aspherical lenses and experience the difference that advanced optical technology can make.